How we do what we do

|

|

Artwork is printed onto special vellum paper, using a high definition printer.

|

|

|

|

|

The ‘mask’ is self adhesive and laid onto the glass. Measuring carefully, the mask is finally positioned and rolled down firmly.

|

|

|

|

A special ‘light sensitive’ film is placed at the bottom of an exposure unit. the artwork (above)

is placed on top of the film. UV light shines through the art work page, “cooking” the light sensitive film beneath. Artwork (black text/images) protects those areas on the film directly below and it remains “raw”.

|

|

|

|

A clear plastic

carrier is removed

from the film.

|

|

A wire wheel, run over the mask,

releases air bubbles

|

|

Tape is placed

around the mask, to protect the glass.

|

|

|

The “cooked” parts remain. We call this a Mask, but it’s often referred to as a Stencil or Resist.

|

|

The film is placed in a Washing Out Unit. Using fresh, warm water, the “raw” parts of the film are washed away.

|

|

|

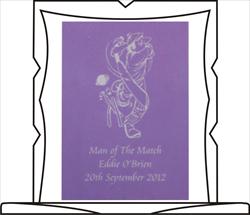

Inside an industrial sandblasting cabinet, fine aluminium oxide is blasted against the mask. “Cooked” areas repel the blasting, while clear, unprotected areas of glass are deeply engraved.

|

|

|

The Mask is dried using warm air. It becomes ‘tacky’ on one side. Now it is ready to be applied to the glass

|

|

|

|

Visit a Glass Engraver's website to Find Out More